Building C1, Laser Industrial Park

+86 19852658006

sales@jshylaser.com

In recent years, with the development of oil and gas industry, the number of drilling and development of highly deviated wells, horizontal wells, multi-bottom wells and branch wells at home and abroad is increasing. Using laser to cut oil slotted pipe is one of the typical applications of laser cutting technology in petrochemical industry.

In the process of oil drilling, sand control in loose formation is one of the most critical parts in oil well completion and oil production engineering design. Generally, a large number of small gaps are processed around the pipe to block most of the sand layer, while laser cutting can cut the gradient slit with wide outside and narrow inside or narrow outside and narrow inside, which makes the oil screen slit pipe have better performance.

Laser cutting of screen pipe is a chemical reaction process in which the surface material of screen pipe is vaporized or changed in color by using the characteristics of high energy and high density of laser to irradiate the surface of screen pipe.

The method of laser cutting of screen pipe belongs to non-contact machining, which not only does not cause tool wear, but also can ensure the cutting accuracy. In addition, usually, the screen pipe is cut by laser, which can improve the automation degree of the project and greatly improve the processing efficiency. Usually, it only takes a few seconds to process a seam, which is several tens of times the machining efficiency.

The main features of laser cutting are:

●It can cut gradient slits with wide outside and narrow inside or narrow outside and inside, so that the oil screen seam pipe has better performance;

The laser beam is easy to guide, focus, realize direction change, easy to realize automatic processing, and obtain better processing accuracy, which is an extremely flexible processing method;

●The efficiency of laser cutting is high, usually it only takes a few seconds to process a seam, which is dozens of times the efficiency of mechanical processing;

● Robots can be used for laser processing in harsh environments or places that are inaccessible to others.

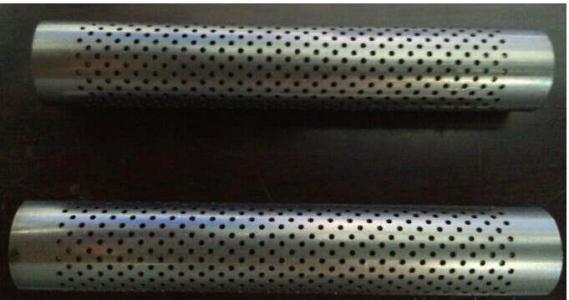

Sample display:

If you have any questions you’d like to ask, feel free to contact us by email.

Pioneer of fiber laser application equipment in China